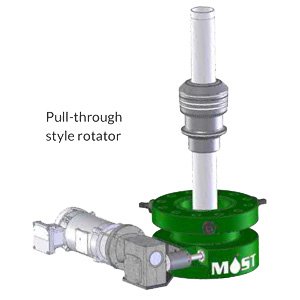

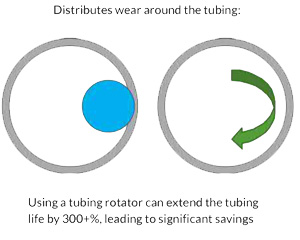

The Surface Tubing Rotator reduces production costs, extending the life of the production tubing by allowing the entire inside circumference to wear evenly. The rotator becomes part of the wellhead assembly as it sits between the wellhead and blowout preventer. The rotator is designed to work with both rod pumping systems and progressive cavity pumps

Features:

- Designed and tested to API 6A specifications

- Patented technology

- The worm gear and rotor are completely sealed to prevent clogging and extend service life

- Nitrided parts to prevent galling

- Shear collar prevents over-torquing on the tubing

- Easy to install

- Rotation rate: about 1.5 revolutions per day with electric motor