The time has come, it is time that you put your oil production on the rise and set your well in order by acquiring all the necessary knowledge about the method of artificial lifting by continuous gas lift, or better-known CGL, used for decades to optimize production in complex wells due to the high viscosity of the oil in the deposit.

In case you do not know or remember, the use of a continuous gas lift system in a non-producing or low production well is a common method of artificial lifting used by oil companies worldwide for the extraction of heavy oil. It is known as the most effective of all artificial lifting methods, possibly because it is the closest to natural oil production. The simplicity of operation of the artificial lift by injecting gas into the well points of injection leads to an increase in its frequency of use as resources in the deposits become scarce.

Why is it recommended to implement CGL?

One of the forces that allow or facilitate the extraction of oil is the difference in pressure and temperature between the reservoir and the well, but for this force to take effect, the viscosity of the oil in the extraction column must be such that it allows continuous flow due to the pressure differential mentioned, when this occurs we will be in the presence of a well with natural oil production, but it is not the most common, when the viscosity of oil along the well is high, the natural pressure differential between reservoir and surface is not enough to allow natural flow production is diminished, and we are in the presence of a well where it is recommended to use gas lift performance. The wells where this method is used are usually deep wells, high energy or high static pressure in the reservoir, around 150 lpc/ 1000 feet and high or medium production rate, around 200 barrels per day. It is also important to take into account the availability of gas on-site and applicability insight rate to supply the system.

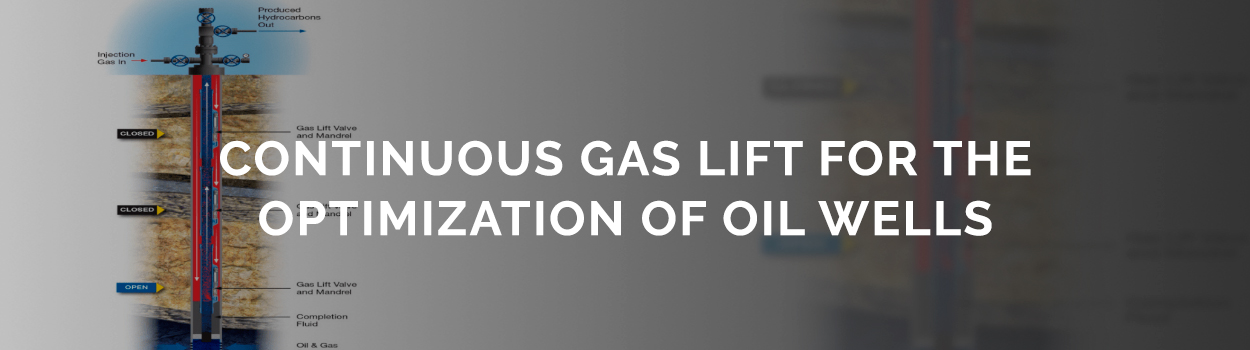

The function of continuous gas injection process is carried out through valves located at different depths of the well, these valves are in direct contact with the production flow, connected directly to the source of compressed gas on the surface, the valves are strategically disposed of according to the required production needs, the depth of the well, the type of crude oil that is extracted, among other factors that in turn define the number of valves to be used. The injection valves will allow the gas to pass gradually, from the deepest section of the well, where the pressure is equal to the reservoir pressure, so the gas source pressure must be higher for the gas to penetrate the well. The rest of the valves placed will open gradually as the movement of the fluid is achieved, this process reduces the effective density and, therefore, the hydrostatic pressure of the oil column, which leads to a gradual and favorable increase of the differential pressure in each section of the well and with it the increase in production.

What are the CGL configurations?

The CGL has two possible configurations, tubular and annular, in the tubular configuration, the gas remains under pressure in a pipeline that surrounds the production pipeline, in annular configuration the gas is in a pipeline within the production pipeline. The efficiency of the system is measured by the consumption of gas required to produce each barrel of oil, so it will increase when the exact pressure necessary to achieve the required production rate is injected through the deeper valve, without using other injection valves, gas consumption decreases.

The increase in the differential pressure induced by means of the sand surface from the pressure of the in situ reservoir helps the produced fluid to flow towards the surface making the oil or gas efficiently extracted.

The gas injected during the CGL can be recovered and reused in the well again using tools such as the Echometer gas separator, since the separation of impurities is essential to optimize production. It is designed to increase production and reduce maintenance costs of lower volume wells, of this and other implements to increase production. You can get more information in the products section of upcoglobal.com for artificial lifting.

There are many advantages over the implementation of this method of artificial lifting as well as its disadvantages, although they tend to be of little relevance due to the benefits and results it offers. The use of CGL can convert a well of low or medium production into a well of high productivity, and therefore it is recommended to use when you have a high productivity index and a high reservoir pressure. Also when the reservoir is of great depth, when the well presents inclinations, in wells with high production of sand and waste and when there are space limitations for the installation of pumps and heads in the well.

This method is easy to install, is economically feasible, robust and effective in a wide range of conditions; for this and many reasons from UPC Global we recommend it blindly